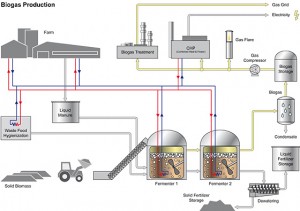

Procedure diagram

This illustration shows the scheme of a two-step biogas process with a mixing tank. In the mixing tank, all input material is homogenised. The feedstock mix consists in most cases of two main components: manure and co-feedstock. All biodegradable, organic material such as energy crops, (maize silage, grass silage, turnips), leftovers, biological waste, food production waste, vegetable fat or potatoes belong to the co-feedstock.

This illustration shows the scheme of a two-step biogas process with a mixing tank. In the mixing tank, all input material is homogenised. The feedstock mix consists in most cases of two main components: manure and co-feedstock. All biodegradable, organic material such as energy crops, (maize silage, grass silage, turnips), leftovers, biological waste, food production waste, vegetable fat or potatoes belong to the co-feedstock.

From the mixing tank the feedstock is transported to the main fermenter. In this fermenter the degradation process of the organic components is effected by means of microorganisms. The secondary fermenter is responsible for the increase of the general degradation degree and the further fermentation. Flammable biogas containing methane is produced in the fermenter as well as in the secondary tank. The fermented feedstock is stored in the final storage tank until it is brought out into the fields as valuable manure.

The biogas is collected in the gas accumulator which is installed on the roofs of the fermenters. From the roof, the biogas is transported into a gas preparation system consisting of desulphurization, drying and compression before it is finally transformed to power and heat by a combustion process in the Combined Heat and Power unit (CHP). The heat produced (80-100°C hot water) can be used for heating purposes. Due to economical reasons, the produced power is normally fed in to 100 % and remunerated as per the conditions of the Renewable Energy Law (EEG)

English

English Ελληνικα

Ελληνικα

Procedure diagram

Procedure diagram